Contact 1-800-314-3578

- Item has been successfully added to cart

- Sign In / Register

- 0 Cart

- Quick Order Pad

- Help

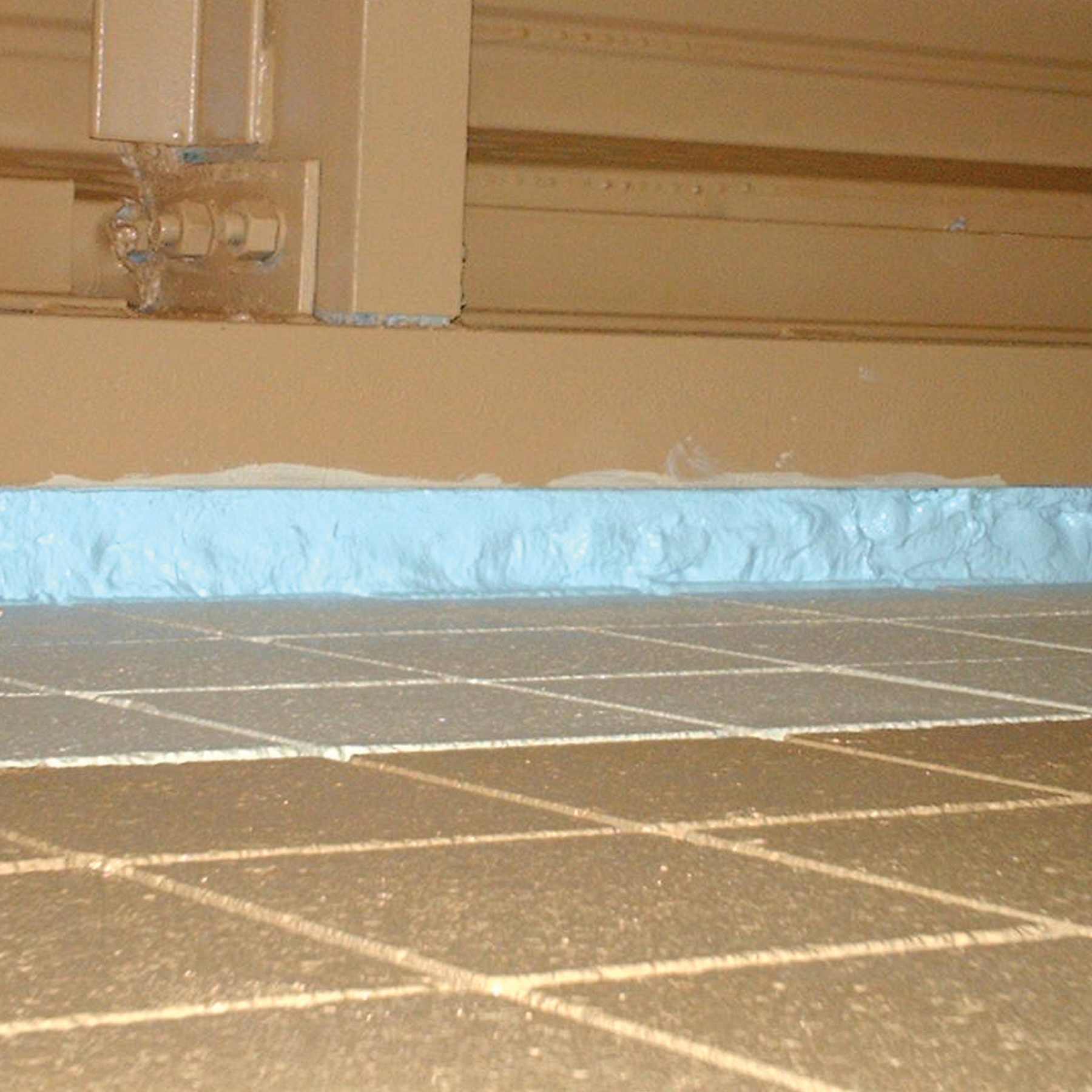

SpecSeal® AS200 Elastomeric Spray is a latex-based elastomeric firestop spray for construction joints and perimeter fire barrier applications. AS200 cures to form a durable seal that resists the passage of the products of combustion while accommodating for high dynamic joint movement.

SpecSeal® Elastomeric Spray, Model: AS200, 5 gal Net Content, Pail Container, Composition: Aluminum Trihydrate, Titanium Dioxide, Crystalline Silica, Paste Form, Pale Blue, Mild Acrylic Odor/Scent, Dry Time: 2 hr, 1155 cu-in Coverage Area, 7.5 pH, 1.25 Specific Gravity, Boiling Point: >212 deg F, 622 deg F Flash Point, 23 g/L VOC, 130,000 cPs Viscosity, Water Base, Density: 10.7 lb/gal, 24 months Shelf Life, Fire/Smoke Rating: 10 Flame, 0 Smoke, Flammability Limit: 0, Application Method: Brush, Spray, Trowel, Evaporation Rate: >1, 40 to 95 deg F

| Application Method | : | Brush, Spray, Trowel |

| Base Type | : | Water |

| Boiling Point | : | >212 deg F |

| Color | : | Pale Blue |

| Composition | : | Aluminum Trihydrate, Titanium Dioxide, Crystalline Silica |

| Container Type | : | Pail |

| Coverage Area | : | 1155 cu-in |

| Density | : | 10.7 lb/gal |

| Dry Time | : | 2 hr |

| Evaporation Rate | : | >1 |

| Fire/Smoke Rating | : | 10 Flame, 0 Smoke |

| Flammability Limit | : | 0 |

| Flash Point | : | 622 deg F |

| Form | : | Paste |

| Model | : | AS200 |

| Net Content | : | 5 gal |

| Odor/Scent | : | Mild Acrylic |

| Shelf Life | : | 24 months |

| Specific Gravity | : | 1.25 |

| Temperature Rating | : | 40 to 95 deg F |

| VOC Content | : | 23 g/L |

| Viscosity | : | 130,000 cPs |

| pH Range | : | 7.5 |

- Applied with airless spray equipment

- Highly flexible to accommodate for dynamic joint conditions

- Tested for up to 4 hr fire resistance rating when tested to ASTM E1966/UL 2079

- Water-based for easy installation and cleanup

- Non-halogenated

- Thixotropic for high-build application

- Auto bonding

- Safe, no solvents, no asbestos, no PCB's, no inorganic fibers

- Water-resistant

- Low abrasion for longer pump life and less maintenance

- Tested with spray applied fire resistive materials (SFRM)

- Paintable when dry

Instruction/Installation Sheet

Instruction/Installation Sheet